Knit Lines Injection Molding

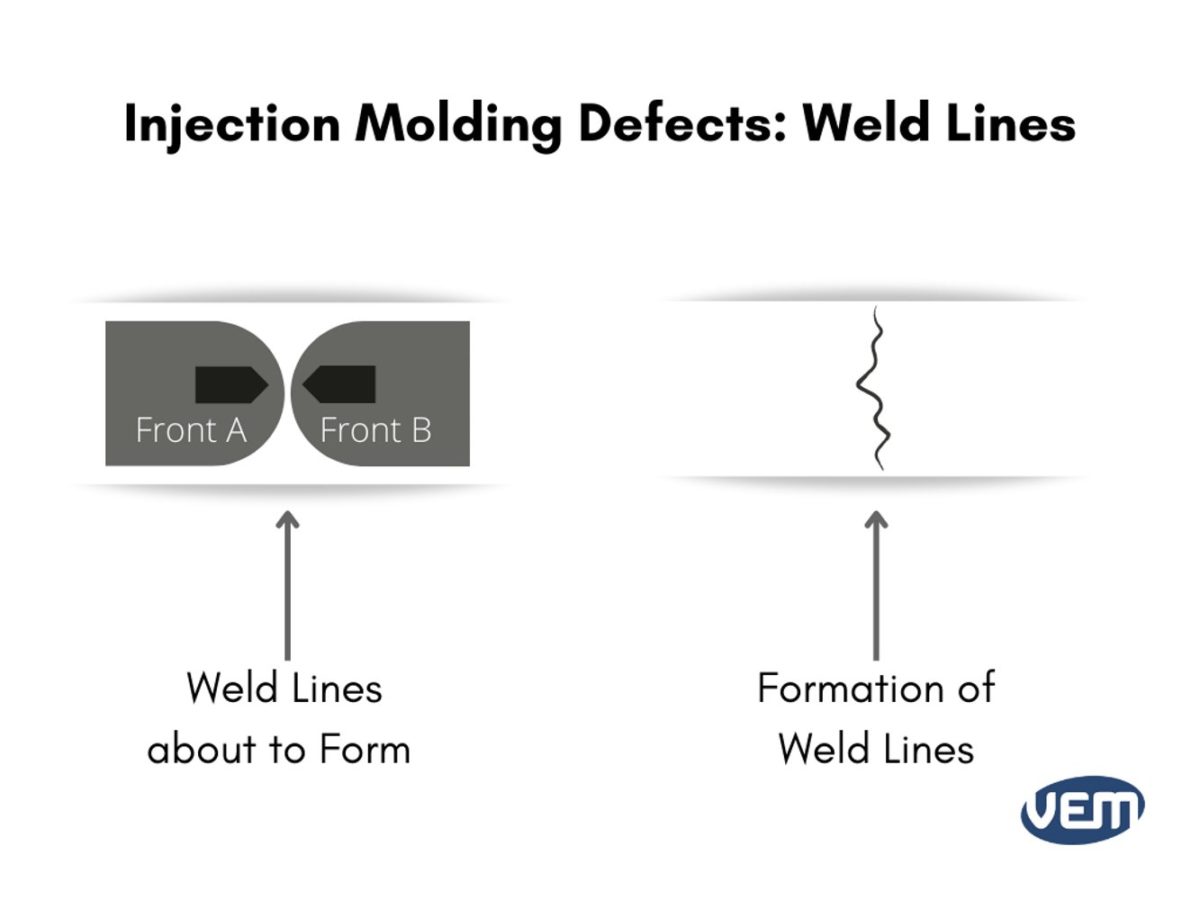

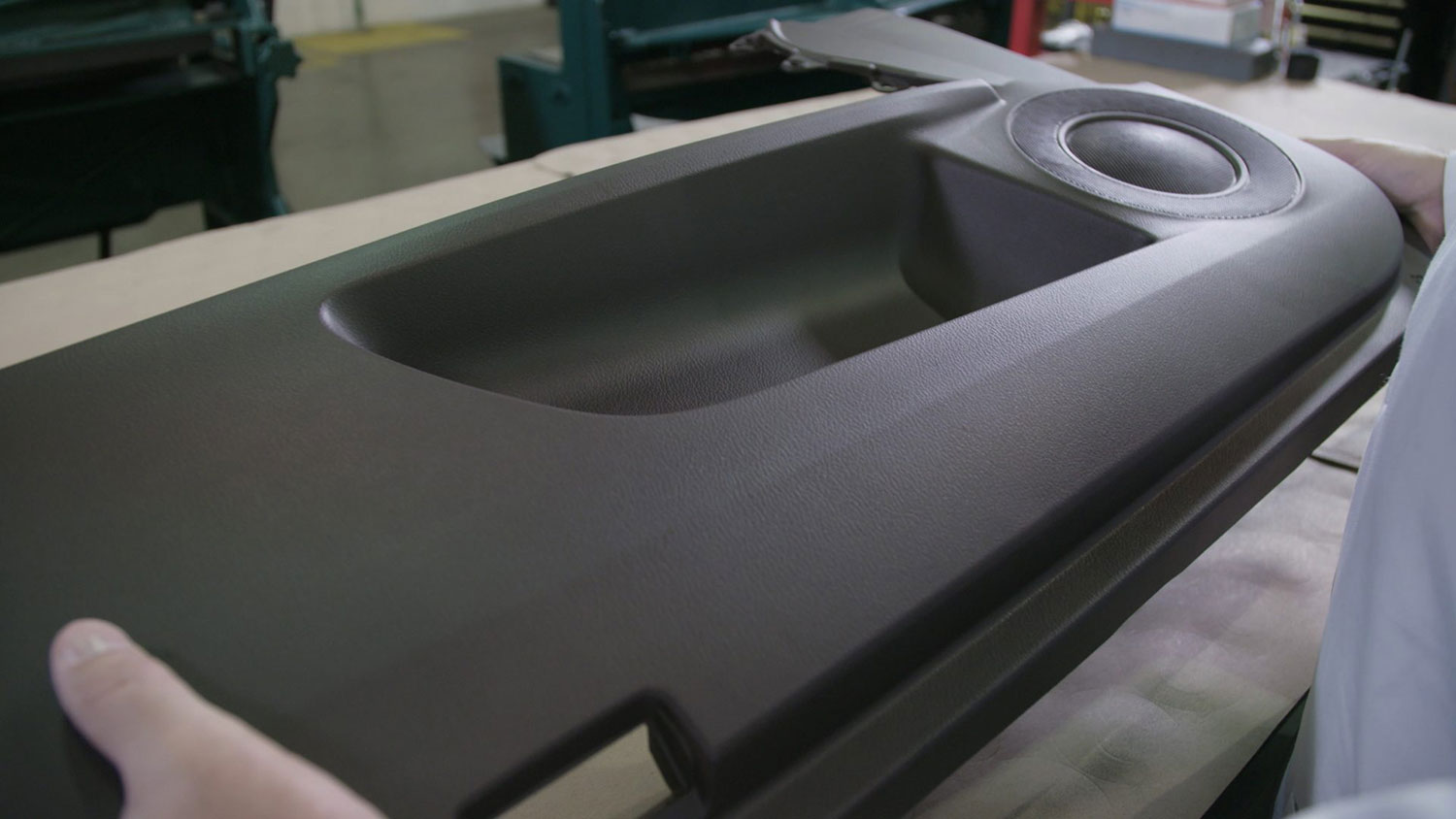

Knit Lines Injection Molding - Web founder, injection molding solutions. Meld and knit lines are actually. Timing and temperature are significant contributing factors when it comes to flow and knit line. Web prevent flow and knit lines during the injection molding process. Machine tools · timeline · steel Web knit lines appear to be a faint line or a crack in the finished part after it comes out of the injection mold. Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí. Weld lines may appear like seams or scratches,. Knit lines are formed when two or more plastic flow fronts collide and solidify or “knit” together during the. Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. Web weld line occurrence in plastic injection molded parts. Web how to eliminate knit lines in injection molding. Weld lines may appear like seams or scratches,. Plastic injection molding is an efficient and affordable process for designing custom prototypes. Web knit lines are considered molding defects, and occur when the mold or/and material temperatures are set too low: Web a knit line is any line, visible or not, where two resin flows meet. Web how to eliminate knit lines in injection molding. Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web. Knit lines are formed when two or more plastic flow fronts collide and solidify or “knit” together during the. This line typically emerges when. What are knit lines, and how can you avoid them? A knit line is formed when two or more plastic flows collide and solidify or knit together in the middle of a part during the injection. Web a knit line is any line, visible or not, where two resin flows meet. Web three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. Web weld line occurrence in plastic injection molded parts. They appear around holes or seams of an injection. Learn more about the knit lines in. Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. They appear around holes or seams of an injection. Web three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. This line typically emerges when. Web a weld line, often referred to as a knit. Web knit lines in injection molding are phenomena that occur when two flow fronts of molten plastic material meet and solidify without bonding completely. Web prevent flow and knit lines during the injection molding process. Meld and knit lines are actually. Web knit lines are considered molding defects, and occur when the mold or/and material temperatures are set too low:. Web jeremy williams, consultant/trainer, rjg. Thus the materials will be cold when they meet, so that. Web founder, injection molding solutions. Machine tools · timeline · steel Web knit lines appear to be a faint line or a crack in the finished part after it comes out of the injection mold. Web knit lines appear to be a faint line or a crack in the finished part after it comes out of the injection mold. Meld and knit lines are actually both different. Web weld line occurrence in plastic injection molded parts. Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web prevent flow. Web weld lines (also called knit lines) are surface defects that form during mold filling when flow fronts come together at sufficiently small interface angles. Meld and knit lines are actually both different. Web founder, injection molding solutions. Machine tools · timeline · steel Weld lines may appear like seams or scratches,. Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí. Web founder, injection molding solutions. Web prevent flow and knit lines during the injection molding process. Thus the materials will be cold when they meet, so that. Web knit lines in injection molding are phenomena that occur when two flow. Web prevent flow and knit lines during the injection molding process. Web knit lines in injection molded parts can range from harmless to unsightly to a serious structural problem. Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí. Machine tools · timeline · steel Thus the materials will be cold when they meet, so that. They appear around holes or seams of an injection. Web knit lines, weld lines, mold lines, or flow lines in injection molding are faint lines that become visible on certain plastic parts. Web knit lines are considered molding defects, and occur when the mold or/and material temperatures are set too low: Present no problem at all,. Web knit lines appear to be a faint line or a crack in the finished part after it comes out of the injection mold. A knit line is formed when two or more plastic flows collide and solidify or knit together in the middle of a part during the injection molding process. Web founder, injection molding solutions. Web a knit line is any line, visible or not, where two resin flows meet. Depending on the design of the mold and the material being injected, a knit line may: Web a weld line, often referred to as a knit line, represents the junction where two flow fronts converge during the molding process. What are knit lines, and how can you avoid them?

What Are Knit Lines in Injection Molding, and How Do You Prevent Them

What is a Knit Line in Injection Molding?

Molding Defects Weld Lines

What Are Knit Lines In Injection Molding? Rex Plastics

What is a Knit Line in Injection Molding?

What is a Knit Line in Injection Molding?

Eden Ashley It's About The Knit Line Molding, Stupid!

Weld Line (Knit Lines) in Injection Molding │20220816T072815.230Z│Blog

Injection Mold Flaws & How to Prevent Them Flow Lines, Knit Lines, & Blush

![]()

Injection Molding Weld Line Plastopia

Meld And Knit Lines Are Actually.

This Line Typically Emerges When.

Web How To Eliminate Knit Lines In Injection Molding.

Web Knit Lines In Injection Molding Are Phenomena That Occur When Two Flow Fronts Of Molten Plastic Material Meet And Solidify Without Bonding Completely.

Related Post: